Facilities – Pressure Die Casting Machines

- PDC ZITAI 900T: 1 Nos

- PDC 730 T: 2 No

- PDC 650 T: 2 Nos

- PDC 560 T: 1 Nos

- PDC ZITAI 420-T: 4 Nos

- PDC TOYO 350 T: 1 No

- PDC ZITAI 250 T: 6 No

- PDC-180 TON: 16 No

- PDC-120 TON: 3 No

- CHAMBER: 60T-1 No.2

Total: 36 Die Casting Machines

SPM’s FOR MACHINING

Drilling S.P.M.

18 Nos

Tapping S.P.M.

03 Nos

Drilling Machines

24 Nos

Tapping Machines

09 Nos

Reverse Tapping M/C

1 No (Upto 20mm)

Finishing Machines

- Buffing Machines: 7 Nos.

- Vibro Machine: 5 Nos.

- Ultrasonic Cleaning Machine: 1 No.

- Shot Blasting Machine: 4 Nos.

.jfif)

Tool Room Setup

- VMC BFW45TC20 : 4 Nos

- WIRECUT ULTIMA : 4 Nos

- EDM RAPID DRILL : 1 No

- MILLING MACHINE : 2 Nos

- SURFACE GRINDER : 2 Nos

- LATHE MACHINE : 3 Nos

- DRILL MACHINE : 2 Nos

- EDM ZNC/CNC : 2 Nos

- RADIAL DRILL M/c : 1 No

Machine Shop

CNC – 14 Nos.

VMC – 7 Nos (with Rotary Table)

Surface Treatment

PT LINE, COATING BOOTH, OVEN

Different Colour Powder Coating / Surface Treatment

Laboratory Equipments & Testing Facility

- X-RAY – 3D & CT (X-AVIS, KOREA): 2 Nos

- Coordinate Measuring Machine (CMM) (HEXAGON): 3 Nos

- Vision Measuring Machine (VMM) (QS Metrology)

- Universal Testing Machine (UTM) (Up to 50 KN, CHINA)

- Spectro (Al & Zn Base) (Metal Power): 2 Nos

- Density Measurement

- Refractometer

- Stereo Microscope

- Dye Penetration Tester

- K-Mould

- Vaccum Testing

- Radioactivity Tester

- Conductivity & pH Meter

- DFT Tester

- Hardness Tester

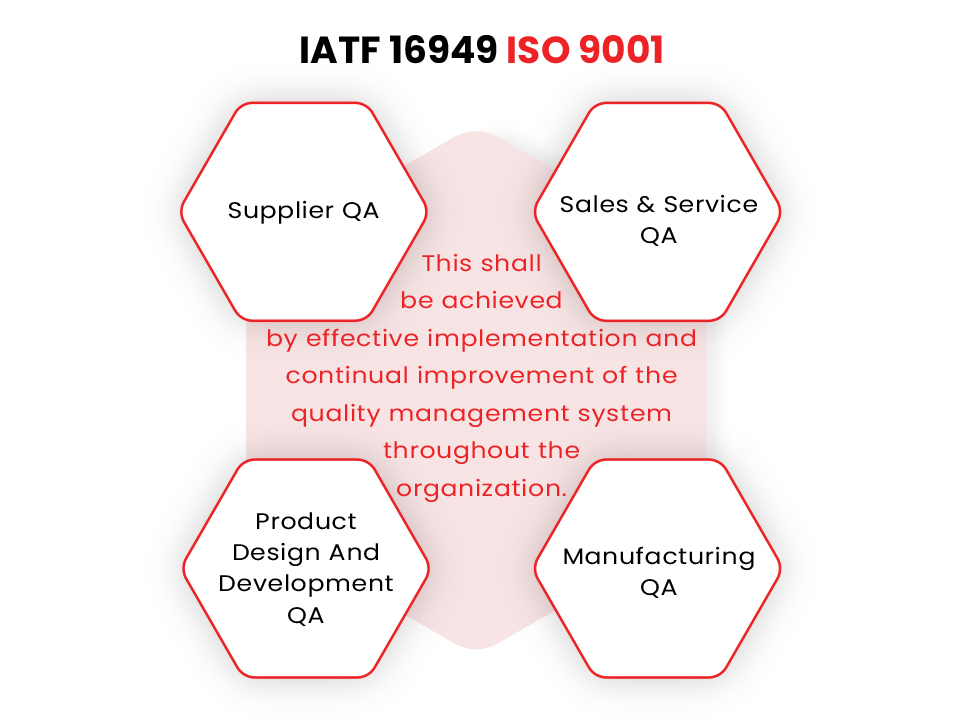

Quality Policy & Objectives

As a veteran in manufacturing of Auto & Engineering components, we remain committed to set the highest standards and deliver quality products. We always endeavour to make the best quality products not only by using the right kind of raw materials but also using quality management principles in all processes and continually improving the same. Ensuring safety principles for our staff & workforce is one of our prime objectives.

Our certifications include ISO 9001:2015, IATF16949:2016, ISO 14001:2015, OHSAS 18001-2007 guaranteeing highest level of compliance to quality and defect prevention.

Our philosophy believes not only in satisfying the customer but delighting the customer through our commitment to the product quality and on-time delivery. To ensure the compliance with customers’ requirement, each and every employee is aware of their responsibility and is committed individually towards achieving our goal of zero defects. Customer feedback is recorded and improvement suggestions are executed.

Techniques

We use the 5 M MAGIC Formula to serve our Customers:

- Material – with the right analysis to meet the customers requirements

- Men – with long experience and rigorous training

- Machines – highly controlled and well maintained

- Method – of testing to gain customers' confidence

- Management – supported by the TSI6949 Quality System to ensure maximum efficiency

.jfif)